Global chief supply chain officers (CSCOs) believe that supply chain disruptions, including financial pressures (72%), evolving customer demands (46%), operational complexities (40%), supplier failures, and others, are the top challenges they encounter. These challenges are a roadblock to the smooth functioning of almost every supply chain and logistics business. To deal with them all, it is important to integrate technologies, especially AI data analytics.

AI data analytics enables supply chain companies and officers/managers to detect supply chain risks, forecast disruptions, and make data-driven decisions. AI data analytics for supply chain risk management enables companies to have a forward-thinking approach to get immense benefits, including increased supply chain resilience and agility, improved cost control, and others.

Let’s dig deeper to know everything about the use cases and role of artificial intelligence data analytics in supply chain risk management. The blog also spills the beans on the technologies that run in the background to make efficient and data-backed SCRM.

What is Supply Chain Risk Management?

Supply chain risk management (abbreviated as SCRM) involves identifying, assessing, and eliminating obstructions or disruptions in the supply chain. These disruptions, such as natural calamities, supplier failures, operational inefficiencies, ESG, cyberattacks, and others, impact the cost and time of moving goods, offering services, or providing information across the supply chain.

Supply chain management can be done in two ways: traditional and using AI-powered data analytics. Let’s read further to know more about both.

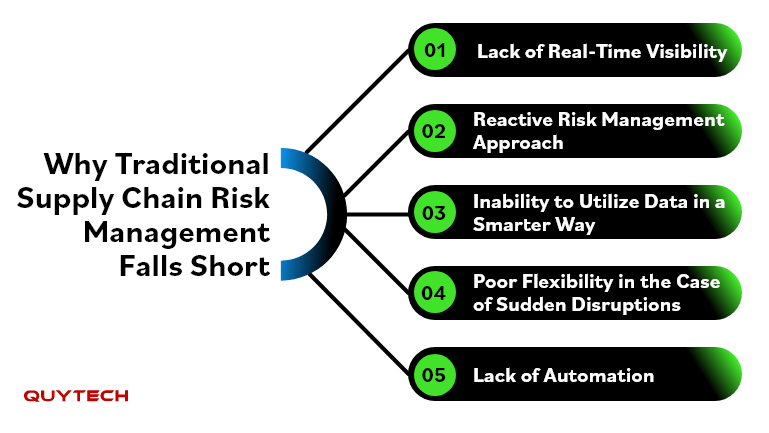

Why Traditional Supply Chain Risk Management Falls Short

Traditional supply chain risk management depends on historical data and human effort to perform required processes. This may not work well in today’s interconnected global environment, where any risk or disruption may occur at any time. These disruptions can impact a business’s bottom line, build a negative reputation, and cause other problems.

So, before you know about the role of AI data analytics in supply chain risk management, let’s understand the shortcomings of traditional SCRM:

#1 Lack of Real-Time Visibility

Conventional SCRM systems work with outdated data, as there are no means of auto-training on new data. This makes it difficult for businesses to predict emerging risks in real-time, which further causes financial losses.

#2 Reactive Risk Management Approach

Human professionals assigned to do risk management consider past events and assumptions, which may provide solutions to the problem that occurs, but don’t provide any means to anticipate the problem, such as supplier failures, geopolitical changes, and more, before it happens.

#3 Inability to Utilize Data in a Smarter Way

Almost every business, including the supply chain, generates humongous amounts of data. With traditional data management and processing techniques, it is difficult to bring out critical insights. It may lead a business to miss opportunities and identify gaps.

#4 Poor Flexibility in the Case of Sudden Disruptions

In case of any disruption, outdated or conventional systems don’t respond immediately or quickly to provide an alternative solution for the smooth flow of goods and services. This may impact supply chain performance during such situations.

#5 Lack of Automation

Every process or operation performed in conventional supply chain risk management settings requires human effort and time, which may sometimes slow down the decision-making process, mainly in the case of high-pressure situations.

How AI Data Analytics Transforms Supply Chain Risk Management

AI-powered data analytics in supply chain risk management transforms the way risks are predicted and managed. Traditional systems for the same rely on static data, but the integration of artificial intelligence into supply chain risk management brings predictive, prescriptive, and adaptive risk management.

The technology enables the SCRM systems to process and analyze raw as well as structured data in real-time. It can provide insights associated with suppliers’ performance, weather, geopolitical events, inventory levels, and other similar aspects to make it easy to discover patterns, identify anomalies, and raise alerts before the issue even occurs.

An AI data analytics in supply chain risk management transforms:

- Static reporting into real-time intelligence for continuous visibility into supply chain risks and performance.

- Historical trends in predictive forecasting by considering multiple parameters to predict disruptions before their occurrence.

- Guesses to data-backed decisions by providing evidence-based insights for risk prioritization and decisive decision-making.

- Scheduled assessment to real-time risk scoring to update stakeholders about new data and events.

Similar Read: AI in Supply Chain Management: Navigating the Future of Logistics

What are Some Key AI Technologies that Facilitate Smarter Supply Chain Risk Management

Modern supply chains deal with several uncertainties and require a system that is not only resilient but also provides strategic insights to overcome current issues and predict the ones that may happen during the flow of goods and services from the source to the destination. Building such a system requires leveraging top technologies like ML, predictive analytics, NLP, computer vision, and others.

Let’s read more about how top technologies run in the background to make data-powered supply chain risk management possible:

#1 Machine Learning

ML algorithms are capable of processing and assessing historical as well as real-time supply chain data to self learn and provide accurate outcomes while detecting patterns, anomalies, and possible obstructions or risks.

Basically, the technology utilizes supervised learning models, ensemble algorithms, and decision trees to offer predictive risk modeling.

#2 Predictive Analytics

Predictive analytics is used to forecast demand fluctuations based on multiple factors like market conditions and seasons. It enables supply chain managers to effectively balance supply and demand while preventing inventory overflows or stockouts.

Read More: How to use AI Predictive Analytics For Forecast Business Performance

#3 Natural Language Processing

With NLP algorithms, supply chain managers can detect early signs of disruption. The technology can make the most sense of unstructured data collected from various sources to identify geopolitical and environmental risks that may impact suppliers and the entire supply chain.

#4 Computer Vision

AI-enabled image and video analytics systems can be placed in manufacturing plants or warehouses for operation monitoring. It can help detect the condition of goods to minimize quality-related problems and ensure workers’ safety.

Explore More: Data Analytics in Manufacturing: Simplifying the Data with AI

#5 Smart Automation

Artificial intelligence, together with robotic process automation, can automate decision-making and even build strategies to deal with supply chain risks. Reduced manual intervention makes the process more efficient, accurate, and time-efficient.

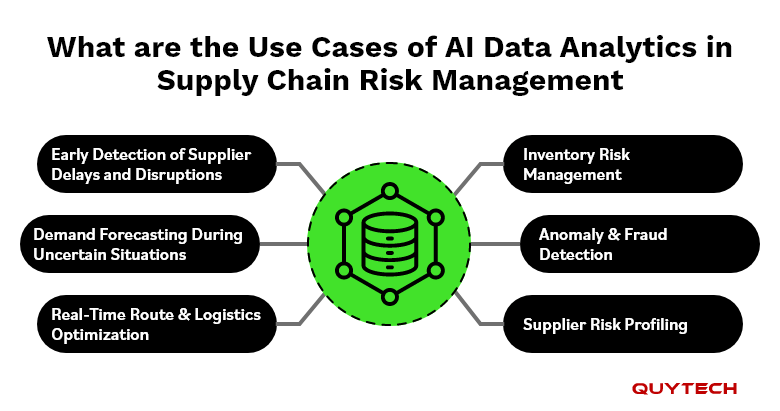

What are the Use Cases of AI Data Analytics in Supply Chain Risk Management

Now that you know enough about SCRM, it is time to provide answers to the most important question, i.e., “What is the role of data analytics in risk management?” Here is how supply chain analytics helps in risk management:

#1 Early Detection of Supplier Delays and Disruptions

Artificial intelligence-powered data analytics, when integrated into traditional supply chain risk management systems, can auto-collect and analyze historical performance data, weather reports, supplier behavior, and other aspects to predict delays, if any.

From supplier risk scoring, disruption forecasting, extracting supply chain risk signals from news and reports, and mapping suppliers’ dependencies, AI data analytics can do anything.

#2 Demand Forecasting During Uncertain Situations

Implementing data analytics in SCRM or data analytics-powered supply chain risk management software can process both structured and unstructured data associated with sales trends, global economic conditions, and market sentiments.

Based on the analysis, it can forecast demands to enable supply chain managers to efficiently manage inventory levels and quickly adapt to evolving market demands and conditions.

#3 Real-Time Route and Logistics Optimization

This is one of the best use cases of data analytics in supply chain risk management. The technology can be implemented to auto-identify efficient routes considering multiple factors (weather, traffic, delivery timelines, etc.), all at once. It can help SCMs to avoid risks that may impact shipment delivery or reliability.

#4 Inventory Risk Management

AI data analytics can provide insights associated with inventory levels. It can continuously analyze consumption patterns, replenishment cycles, lead times, slow-moving items, and other factors to help optimize inventory levels.

#5 Anomaly and Fraud Detection

Fraud and anomalies cause big disruptions in supply chain management. AI data analytics can analyze patterns to flag irregularities in procurement, supplier transactions, billing & invoicing, and other processes to detect fraud. These frauds may go unnoticed with manual analysis.

#6 Supplier Risk Profiling

With AI data analytics, it becomes easy to assess different supplier metrics for diversification and risk profiling. The technology can analyze metrics like suppliers’ financial performance, location risk, environmental, social, and governance, and more to give a risk score to each supplier.

You may also like to read: Generative AI in Supply Chain: Top Use Cases and Benefits

What are the Business Benefits of Using AI Data Analytics in Supply Chain Risk Management

Implementing AI-enabled data analytics in SCRM or using AI-powered supply chain risk management software eliminates risks. It also makes the entire supply chain more efficient and intelligent. Check out some amazing advantages of intelligent supply chain risk management for businesses:

#1 Minimized Operational Downtime

AI data analytics identifies risks in advance, which allows SCM professionals to modify their strategies to avoid risks, such as delays, stockouts, and overstocking. It also ensures better operations management and timely deliveries of goods.

#2 Increased Supply Chain Resilience and Agility

AI data analytics facilitates real-time monitoring of crucial operations while providing predictive alerts in case of sudden disruptions or critical events. This allows supply chain managers to quickly respond to disruptions like supplier problems, demand fluctuations, and delivery delays.

#3 Better Supply Chain Cost Control

When supply chain managers have accurate forecasting in their hands, they can optimize inventories and detect risks before they occur. Supply chain and logistics companies can build proactive strategies that can cut excess costs associated with emergency supply, expedited shipping, and more.

#4 Enhanced Supplier Relationship Management

Effective supply chain risk management, especially when it is backed by AI data analytics, enables businesses to get an accurate picture of suppliers’ performance, reliability, and risk scores. They can do better negotiations and build lasting relationships.

#5 Data-Driven Decision-Making

This is one of the biggest advantages of using AI data analytics for supply chain risk management. With critical insights provided by this technology, stakeholders can make better and confident decisions.

Also Read: IoT in Logistics and Supply Chain Management: Use Cases, and Benefits

What are the Future Trends in Using AI Data Analytics for SCRM

The chances of disruptions in this complex supply chain system are quite normal. A business that can be prepared beforehand for these disruptions, especially by using AI data analytics, can definitely be successful. Apart from this, the business should also have an idea of the upcoming trends associated with AI data analytics in SCRM. Read them all below:

- The use of digital twins will increase. It will enable businesses to simulate scenarios and prepare solutions and strategies to stand strong without impacting their bottom line or reputation.

- Agent-based modelling and autonomous decision-making will enable supply chain companies to make real-time decisions and responses to disruptions with minimal human intervention.

- In the future, we may also see companies moving towards collaborative risk intelligence. This will include collaborating and training AI models without sharing sensitive data for smarter risk detection systems and with complete data integrity.

- In 2026 and beyond, we may see the rise of AI-driven ESG risk monitoring. This will allow supply chain firms to manage non-financial risks and adhere to compliance more proactively.

- Predictive maintenance of supply chain assets is also expected to gain popularity and become a trend in supply chain risk management.

Also Read: Latest Tech Trends in Logistics: Solutions and Examples

Real-World Examples of Using AI Data Analytics in Supply Chain Risk Management

Top companies have already empowered their supply chain management processes with AI data analytics. Here are four examples to look for:

#1 IBM Watson

This world-renowned firm uses AI data analytics to forecast supplier risks. Data analytics assesses weather events, historical and real-time data from multiple sources to give predictions for the same, and suppliers a risk score.

#2 Amazon

Amazon needs no introduction. The tech giant uses AI data analytics to keep a tab on the demand patterns and automate replenishment in the warehouse. It enables the company to keep inventory overflow or stockouts at bay, even during sales and festive seasons.

#3 DHL

DHL uses big data analytics to predict goods transit delays. It also facilitates route optimization, considering multiple factors to ensure on-time deliveries and controlled logistics and supply chain costs.

#4 Unilever

Unilever utilizes data analytics and machine learning to forecast demand with the data collected from point of sale (PoS) systems and social trends. The use of AI data analytics improves forecast accuracy.

Choosing Quytech to Implement Data Analytics and Mitigate Supply Chain Risks

Quytech is the most trusted AI data analytics company that empowers global supply chain startups and businesses to identify, assess, and eliminate risks by utilizing their business data to the maximum.

We can implement data analytics into your existing supply chain solutions and can also develop AI data analytics-powered supply chain risk management solutions from zero to one. These solutions mitigate all types of supply chain risks, including demand risks, supply risks, operational risks, financial risks, environmental risks, technological risks, and political/legal risks.

Customization, scalability, and security are our three core USPs of the AI data analytics solutions that we develop for supply chain companies. Partner with us to utilize the maximum potential of your business data for efficient and effective supply chain risk management and gain a competitive advantage.

Final Thoughts

Supply chain disruptions are unavoidable; however, these can be efficiently and effectively managed with AI data analytics. AI data analytics makes the most of your structured and unstructured business data, along with the data from the market, news, social media, and other sources, to provide you with critical insights for supply chain intelligence.

AI data analytics in supply chain risk management can you predict supplier delays, identify anomalies, improve operational performance, forecast demand, prevent fraud, and optimize supply chains. Read this blog to know inside-out about using data analytics for supply chain risk management.

FAQs

Here are seven types of risks that obstruct efficient supply chain management:

– Demand risk

– Supply risk

– Operational risk

– Financial risk

– Environmental risk

– Technological risk

– Political/legal risk

In traditional settings, a supply chain manager or professional follows these steps to efficiently and effectively manage supply chain risks. However, the entire process can be upgraded by implementing AI data analytics and ensuring smarter risk management.

– Identify risks

– Assess impact

– Prioritize risks

– Develop mitigation strategies

– Monitor and review

Connectivity, collaboration, cybersecurity, and customer-centricity are

They use data to forecast demand, track performance, optimize logistics, and predict disruptions.