A manufacturing industry focuses on a lot more than simply production. It encompasses multiple factors and processes to work on before and during the production process. These include forecasting the demand, managing inventory levels, and maintaining quality standards, along with cost-effective production planning.

With the conventional management system, it can be a tough juggle of activities. But not anymore! The industry 4.0 era has marked the onset of utilizing artificial intelligence, smart factories, and data analytics, giving the traditional manufacturing floor a makeover.

Get ready to explore how data analytics in manufacturing sector is transforming the legacy system. From production planning to cost effectiveness and quality control, all are covered in this blog.

What is Data Analytics in Manufacturing ( AI Fuels Innovation )

The era of simply collecting and presenting data by creating bar graphs and pie charts is long gone. Data analytics is now integrated with artificial intelligence. It now offers insights based on the data collected by utilizing AI and its subsetslike machine learning, predictive analytics, prescriptive analytics, and defect detection.

AI-powered data analytics refers to making use of the features of artificial intelligence in the routine and decision-making processes to reduce inefficiencies and errors and enhance productivity and accuracy.

AI for data analytics in manufacturing sector assists in predicting maintenance, forecasting product demand in the future, optimizing processes, and detecting anomalies. This saves the time, effort, and resources of a company that could get wasted if the decisions are made based on past experiences.

Market Statistics for Data Analytics in the Manufacturing Industry

- As per MMR, the Global analytics market for the manufacturing industry is expected to reach a value of US$42.51 billion in 2030.

- With the largest market share of 58% in manufacturing analytics, the United States led the industry in 2023. As governmental investments and policies supporting its development increase, this expansion is anticipated to pick up even more speed.

- In the upcoming years, North America and Europe are expected to continue to be the two regions that generate the most income for manufacturing analytics providers.

Read More: AI Agents in Manufacturing: A New Era of Excellence

Why the Manufacturing Industry Needs AI and Data-Driven Solutions

An ounce of predictive analytics is worth a pound of unplanned downtime. The manufacturing industry is no longer solely focused on mass production. With the new transformed landscape, choosing a reactive decision-making technique can be a setback. Switching to an AI and data-driven solution is not an option but a necessity.

Manufacturers generate a generous amount of data from every activity conducted across the departments. However, with the legacy system, this data is often not utilized. Artificial intelligence, along with data analytics, utilizes the data created across machinery, supply chains, inventory levels, etc., to make informed decisions. It uses AI features and analytics to predict future requirements, demand, and maintenance needs, and highlights the defects and inefficiencies.

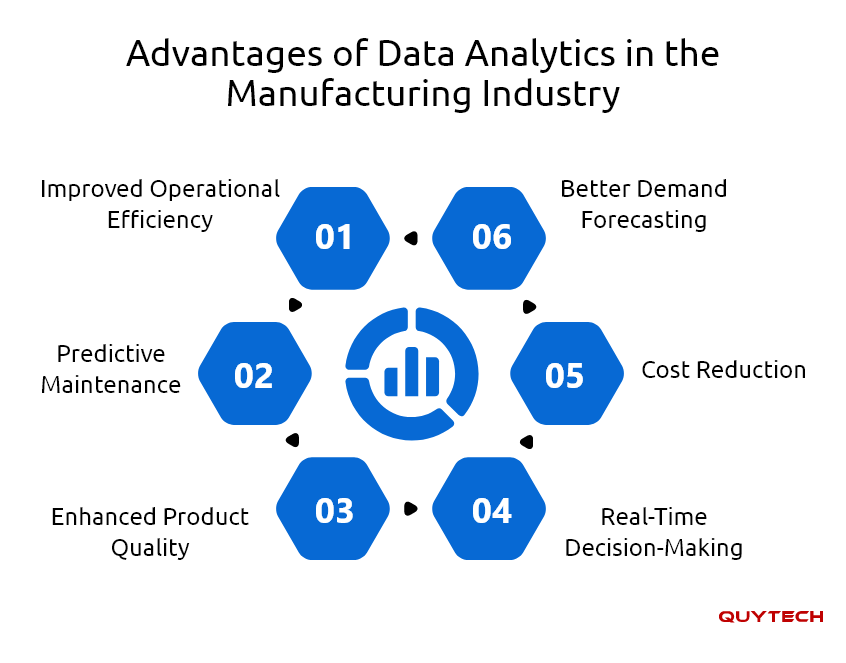

Advantages of Data Analytics in the Manufacturing Industry

Data analytics has powered the factory floors in manufacturing industries in a significant manner. Here are some core advantages of utilizing data analytics in the manufacturing industry:

Improved Operational Efficiency

A manufacturing process consists of multiple steps, from raw material handling to logistics. All these processes utilize resources, machinery, and a specific time duration. Data analytics catches any inefficiencies that occur throughout the process, which would be overlooked under manual care.

Predictive Maintenance

The traditional system looks out for maintenance only when machines break down. Data analytics predicts machine downtime based on the data collected from the sensors installed in the machine. This saves time that could’ve been spent on untimely repairs caused by sudden failure.

Enhanced Product Quality

During the manufacturing process, it is very common for parts and components to have some anomalies. Data analytics detects these defects while processing them immediately. This helps in fixing problems promptly rather than wasting resources and efforts.

Real-Time Decision-Making

Earlier, the decision-making process was dependent on limited data, experience, and intuition. With the help of data analytics, the manufacturing process is now supervised in real time through dashboards and alerts. This assists in solving any arising issues instantly and avoiding inefficiencies.

Cost Reduction

Analytics goes through all the data generated throughout the manufacturing process and creates insights based on that. It identifies underperforming areas like material wastage, overproduction, and overspending, and helps businesses make informed decisions to reduce wastage.

Better Demand Forecasting

Demand forecasting is a very prominent aspect in the manufacturing process. It takes the production decision based on the demand. Analytics helps in aiding better demand prediction as it considers all the data and then gives insights. It utilizes past sales, seasonal trends, customer preferences, etc, to forecast demand accurately.

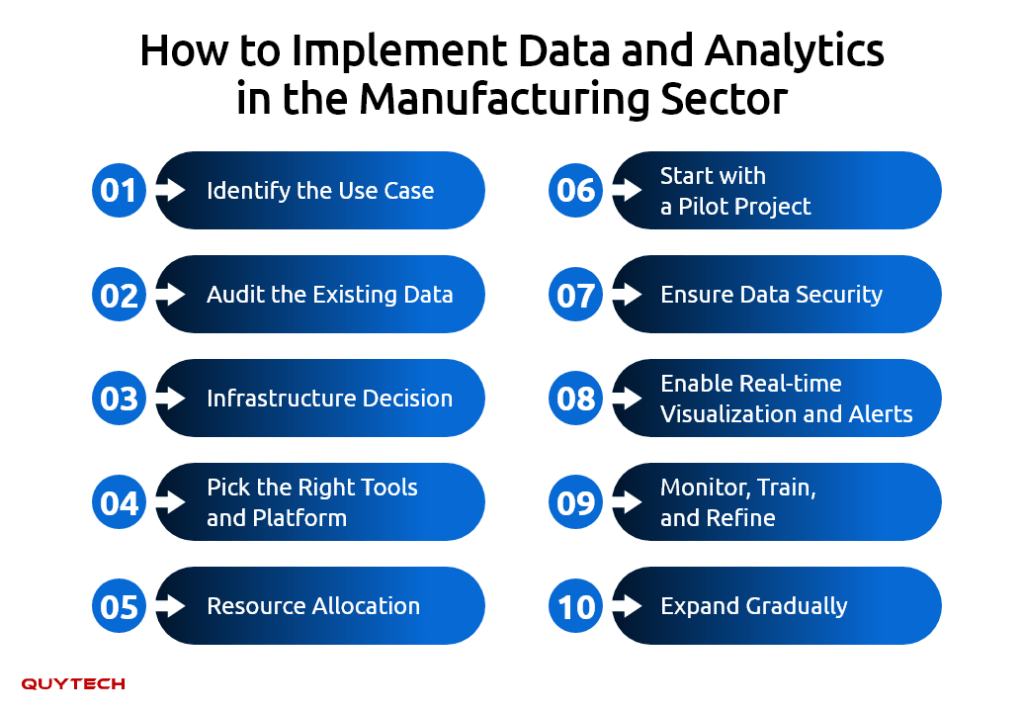

How to Implement Data and Analytics in the Manufacturing Sector

Implementing data analytics in your manufacturing business comes with a series of steps and requirements for a seamless integration. Here is a roadmap for the successful implementation of data analytics in the manufacturing sector:

Identify the Use Case

This step involves identifying the need or cause that is affecting the cost or work efficiency. It could be overproduction or the breakdown of the machinery. Focus on the issues that can be measured and have existing data sources.

Audit the Existing Data

Audit the existing data collected through the machinery, sensors, spreadsheets, etc. This will help you analyze the data collected and utilize it to identify the deviations effectively. The results thereafter can guide on the areas that need early integration of data analytics.

Infrastructure Decision

Infrastructure decision involves choosing the right technology stack required to implement data analytics efficiently. It includes deciding the storage options, which are usually cloud-based, as they collect large amounts of data. Other tools include sensory devices, integration tools, etc.

Pick the Right Tools and Platform

Choose the suitable software based on your needs. Select the tools required to set up the dashboards for monitoring, alert systems for predictive analysis, AI models for defect detection, etc. These should be selected keeping in mind that they integrate effectively with other systems.

Resource Allocation

For seamless integration and implementation of data analytics, you will require an expert workforce including data engineers, data scientists, AI developers, and specialists. If you lack in-house expertise, then you can hire developers for the same.

Start with a Pilot Project

Start with one segment instead of implementing it at every stage. Choose one use case and implement the system there. Go through the results of the implementation and look out for deviations to work on.

Ensure Data Security

When integrating data analytics in the manufacturing sector, you will be collecting a large volume of data. This creates a need for data security as it can be accessed by third parties. Ensure that you incorporate data monitoring and security measures so that it maintains an activity log and access controls.

Enable Real-time Visualization and Alerts

Set up data analytics dashboards and an alert system that updates with the data collected in real-time. It will keep track of the machinery, production rates, errors, etc., and help you take suitable action proactively.

Monitor, Train, and Refine

The implementation of data analytics in manufacturing is not a one-time event. The models need regular training, accuracy testing, and refinement. Apart from refining the systems, staff should also be trained regularly to keep them updated with the latest tools.

Expand Gradually

After the successful implementation in one segment, expand it to the rest of the manufacturing processes, plants, and production lines gradually. Also, extend data analytics to the post-manufacturing process to enhance overall productivity.

Read More: How AI is Proving as a Game-Changer in Manufacturing?

Technologies Driving Data & Analytics in Manufacturing

The working of data analytics is not limited to simply collecting information; it goes beyond spreadsheets. Here are the technologies that help in driving this transformation:

Industrial Internet of Things

IIoT (Industrial Internet of Things) involves setting up smart devices and sensors in the machinery, tools, and systems across the manufacturing floor. These devices send data collected based on their temperatures, speed, etc., to the analytics platform. This creates an interconnected shop floor.

Big Data Platforms

Big data platforms assist by offering a platform to store large amounts of data generated in the manufacturing process. This platform is built to handle the volume and variety of data, enabling manufacturers to analyze it effectively.

Artificial Intelligence and Machine Learning

Artificial intelligence and machine learning play a very prominent role in implementing data analytics in manufacturing processes. It processes the existing and real-time data to offer predictive analysis and insights. It also assists in detecting defects in product quality.

Cloud Computing

Cloud computing involves cloud platforms that allow manufacturers to access, control, and analyze data anytime and anywhere. This gives a cost-effective solution as a single platform is needed to work and get insights into the data.

Edge Computing

Edge computing takes a step further by giving instant analysis. It collects and analyzes at the point it’s generated to enable real-time decision making. It is effective in scenarios where instant action is required.

Digital Twins

Digital twins are a virtual copy of a product or process that exists in the real world. It works based on the sensors placed on the actual product and updates in real-time. It serves as a medium to test changes without actually trying them in real life. It helps in spotting problems early, contributing to better performance.

Common Challenges in Implementing Data Analytics in Manufacturing

While data analytics manufacturing solutions are result-bearing, shifting to them can be a huge change. The following are some of the challenges that a manufacturing company may face when switching from a legacy system to data analytics:

Poor Data Quality

The inconsistent, inaccurate, and outdated data entered manually significantly affects the quality of analysis. It can happen due to human error, defective sensors, and an inconsistent format. Analysis based on poor data can lead to inaccurate analysis and wrong decision-making.

Legacy Equipment

Manufacturing plants that use traditional equipment can face challenges when integrating with data analytics. The legacy machinery is often not fit for implementing technology changes, and even when it is implemented, it can be very costly and technically challenging.

Integration Complexity

Integrating new tools with the existing management systems, like ERP, MES, etc. It can be a challenging task. The data language in these management systems is completely different from that of the analytics tools. The lack of APIs also contributes to the issue.

Lack of Skilled Expertise

The integration of analytical tools with the existing manufacturing systems requires skills and knowledge of the domain. Manufacturing companies may lack the required skilled personnel to make this happen. Without the right partners, the company may struggle to turn its raw data into valuable insights.

Resistance to Change

Integrating analytics is not beneficial if it is not put to use. It can be challenging for manufacturers to trust data-based insights to make decisions, as it can be a huge change to their previous decision-making style. This resistance to technological changes can make it difficult to implement data analytics in manufacturing processes.

High Implementation Cost

Implementation costs of data analytics in manufacturing processes can be high. Many manufacturing companies hesitate to put a huge amount into investing in analytics implementation. Budget constraints and uncertain ROI often limit companies from investing in data analytics.

Read More: How Augmented Reality Streamlines Manufacturing Operations

How Quytech Helps Build Data-Driven Manufacturing Solutions

Quytech helps manufacturing companies by turning their raw data into meaningful insights to make informed decisions. With years of expertise in the field of technology, Quytech offers you the best team of deserving engineers to build AI-assisted data analytics manufacturing solutions, built to suit your style of manufacturing.

We specialize in integrating analytical tools with your existing management systems. With AI and machine learning as the core, the solutions provided effectively give useful insights based on existing and real-time data.

Conclusion

Data and analytics are not just the current trend of the manufacturing industry, but also the bright future. Switching from the legacy systems to analytics does more than give a competitive edge to the manufacturing sector. It is a cost, time, and resource-efficient solution that not only caters to providing insights with data collected but also enables real-time decision making.

With integrated technologies like the industrial internet of things, big data platforms, cloud computing, etc. Data analytics in manufacturing offers smart devices, large volume storage platforms, access to data, and much more. All these features and tech advancements create an interconnected factory floor where every stage and step is actively monitored, making it easy to react proactively in case of any failure.

FAQ’s

No, it is not necessary to buy new machinery to implement data analytics in manufacturing. It can be implemented on legacy machines as well.

Data analytics actively monitors materials, products, and processes in real-time. It detects any defects and sends alert signals, which eliminates the repetition of defects.

Traditional reporting focuses on taking future decisions based on intuition and experience. Real-time analytics focuses on making decisions based on current requirements that are reflected through real-time data.

No, small manufacturing companies can also utilize analytical manufacturing solutions. This will help you in making informed decisions and gaining a competitive advantage.